While the number of machines onsite may be limited, keeping them running for longer can still ramp up productivity.īecause labor costs don’t need to be paid to workers during lights out machining periods, the relative costs of production are reduced. This can significantly increase the productivity and output of the machines. Lights out machining mean that the machines can continue operating for more extended hours without human input, functioning 24 hours a day if necessary. BENEFITS OF “LIGHTS OUT” MACHININGīecause lights-out machining allows production to continue even without any human operator attention, there are a number of advantages. Talk to your precision machining company about whether the pieces and components that you require can be machined lights out. Some models can run when normal company operations have shut down, and the lights would typically be off. However, to produce multiple pieces of the same piece, constant operator attention is not needed so that precision machining can continue unattended outside of working hours.īecause specific precision machines can run without operator attention, typical machines that are capable of running lights out must have bar feeders or multiple pallets.

In precision machining, a human input may be required to create designs and adjust settings on the machines. The processes and machinery functions can be fully-automated, allowing for production to continue with no human presence whatsoever. The technology to allow for lights out machining is increasingly accessible and available. Because the automated processes don’t need human oversight or control, they continue outside of business hours and even overnight hence the term “lights out.” Even after the human workers and employees have gone home, the machines can keep working to produce a higher output. It refers to automated processes and machinery functions that require minimal human input to operate. Lights out machining is a technique or methodology used by precision machining companies and other manufacturers. Here we look at what ‘lights out’ machining is as well as how it can affect the machining process and the final product. Lights out machining is a technique used by some manufacturers and machining companies that can offer a number of benefits if done successfully. “Lights out” machining is a way that precision machining companies can increase productivity and efficiency even further.

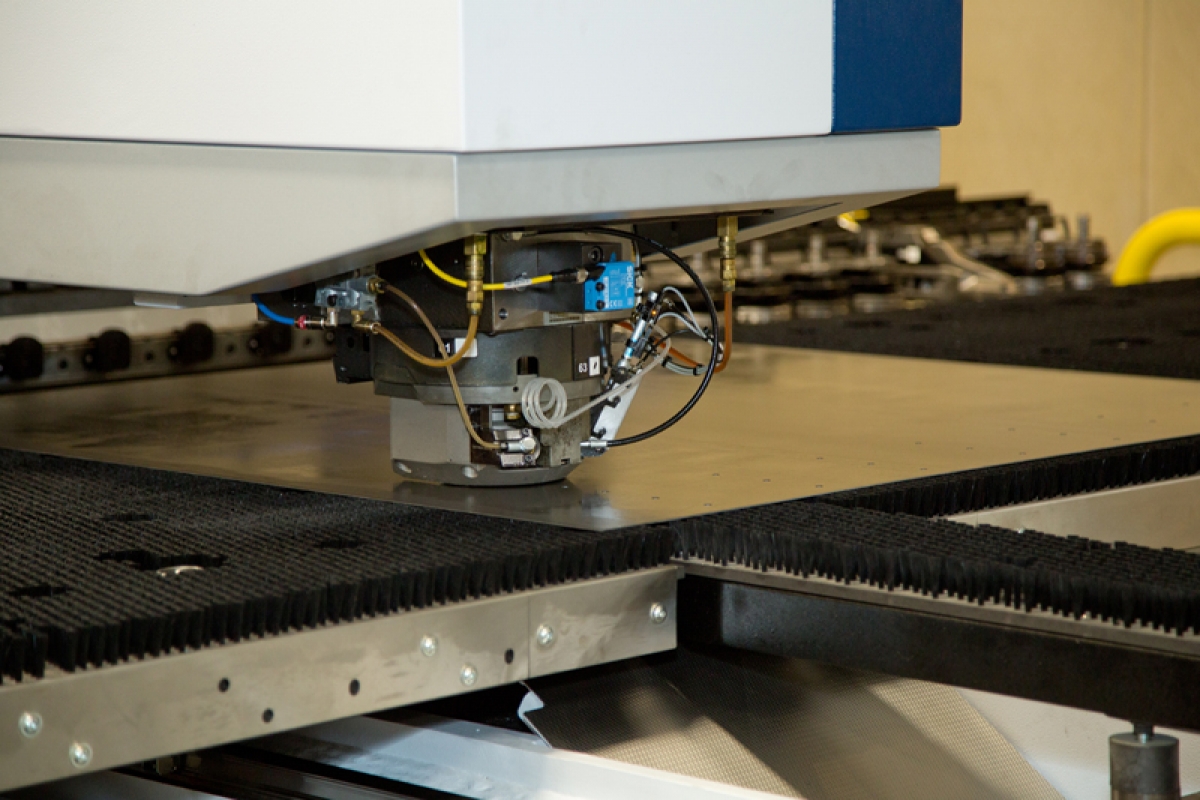

Precision machining allows for the precise and efficient production of even the most intricate parts and components.

0 kommentar(er)

0 kommentar(er)